Could a robot ever autonomously unload a cargo of bagged goods from a ship?

This was the question posed by Voxdale and MVH-group, and to which Act In Time, together with a number of other technology partners, came up with an answer.

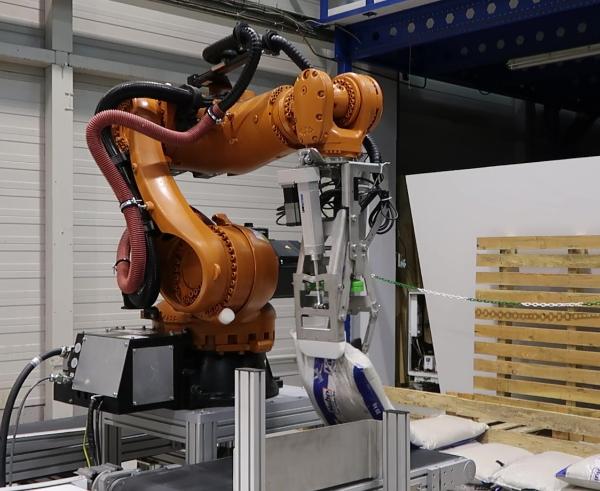

The film at the bottom of this article shows how a robot arm unloads bags of cement from a pallet. The difficulty here is that such bags do not always have the same thickness or strength. Act In Time started working on this issue and, together with the developers at Voxdale, came up with a nice solution for the movement of the gripper.

The PNCE with ball screwl from Unimotion as a linear actuator was combined with a closed loop AZ-stepper motor from Oriental Motor that is controlled via EtherCAT bus of the robotcontroller.

Geweldige verhalen hebben een persoonlijkheid. Overweeg om een geweldig verhaal te vertellen dat persoonlijkheid heeft. Het schrijven van een verhaal met persoonlijkheid voor potentiële klanten helpt bij het opbouwen van een relatie. Dit komt tot uiting in kleine eigenaardigheden zoals woordkeuzes of zinsdelen.

This turned out to be an excellent combination to meet all requirements:

In a first phase, a rapid movement is required that opens or closes the gripper, which is set to position.

Oriental Motor's built-in absolute position encoder which works without battery, guarantees that the correct position is always reached.

As soon as the grippers are closer to the load, they switch to a push force setting. This is also a unique feature of the closed loop technology that makes it possible for stepper motors to be used for applications where torque control is necessary. Thanks to an intelligent mechanical construction, the gripper centers itself around the product, so the same gripping force is achieved, regardless of the thickness of the bag or load.