Xtraflex produces PTFE hoses in a state-of-the art production unit at Lier and is continuously looking for further optimisation and automation. Until recently, behind the extrusion line at the end of the process, the PTFE hose was coupled to a chain. It was up to the operator to keep the chain at the right tension so that the hose ran through the ovens in a controlled manner.

This manual operation was taken over in a recent automation by a 60W brushless DC motor with unique braking action from Oriental Motor. The solution with the BXS offers all the advantages of a servo motor but is more budget-friendly and easier to set up, which also reduces integration time.

Via the digital inputs, the desired speed is selected depending on the process. In addition, an external potentiometer allows the operator to adjust the torque at any time. The set torque determines the braking force and thus the tension on the PTFE hose during the drying process.

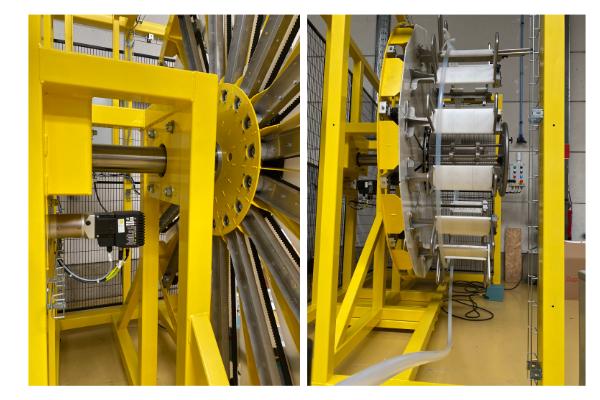

Another need in production is winding the PTFE hoses to length in order to check and package them per order. Given the scale of that project, the company called on the Belsele-based company IAP, a well-known machine builder in the region for special custom-made products.

Tom Eijkelenberg - Project & Development Engineer at Xtraflex: The implementation of the wrapping robot was flawless and, besides saving time for the operator, it also provides certainty about the stability of the process and, consequently, the quality of our product. Given its success, installation has already been duplicated.

Although the reel is very bulky, a compact 750W servo motor with planetary gearbox flawlessly provides the smooth drive with speed and torque control.

Both values are easily adjustable by the operator using potentiometers on the control panel.

The fact that JVL's MAC800 was chosen is due to the surface-mounted driver with built-in PLC functionality.

This greatly simplifies cabling since there is no need to install an electrical cabinet.

So if you need a simple solution to handle fragile products using a robot, do not hesitate to

contact us!

Start hier met schrijven...