Start hier met schrijven...

When developing a new machine, it is important to ensure that the relevant data is available in real time. Electric actuators offer many more options in this area than less intelligent systems. Orientalmotor and Inovance have recently launched products that take this to a new level.

Linking production machines to the Internet of Things (IoT) offers several advantages for industrial processes and production systems. Here are some reasons why companies choose to integrate manufacturing machines with IoT:

Real-time monitoring: By connecting production machines to the internet, companies can collect real-time information about the performance and status of the machines. This allows operators to closely monitor production processes, identify potential problems and intervene immediately if necessary.

Predictive maintenance: Electric actuators can collect data about the wear and function of the machines. By using advanced analytics, companies can predict when a machine might fail or require maintenance. This helps to reduce unplanned downtime and improve maintenance efficiency. This video explains how this works:

Optimalisation of production process: IoT-connected machines can contribute to the optimization of production processes by collecting data on the performance, efficiency and quality of products. This data can be analyzed to make improvements to production planning, increase throughput and reduce costs.

Quality assurance: Sensors on production machines can continuously collect data about product quality. By analyzing this data, companies can quickly intervene if anomalies are detected, reducing the chance of production errors.

Energy-efficiency: IoT can help monitor and optimize the energy consumption of production machines. This contributes to sustainability and cost savings by reducing unnecessary energy consumption..

Supply chain-integration: By connecting production machines to IoT, companies can better align their production processes with the rest of the supply chain.

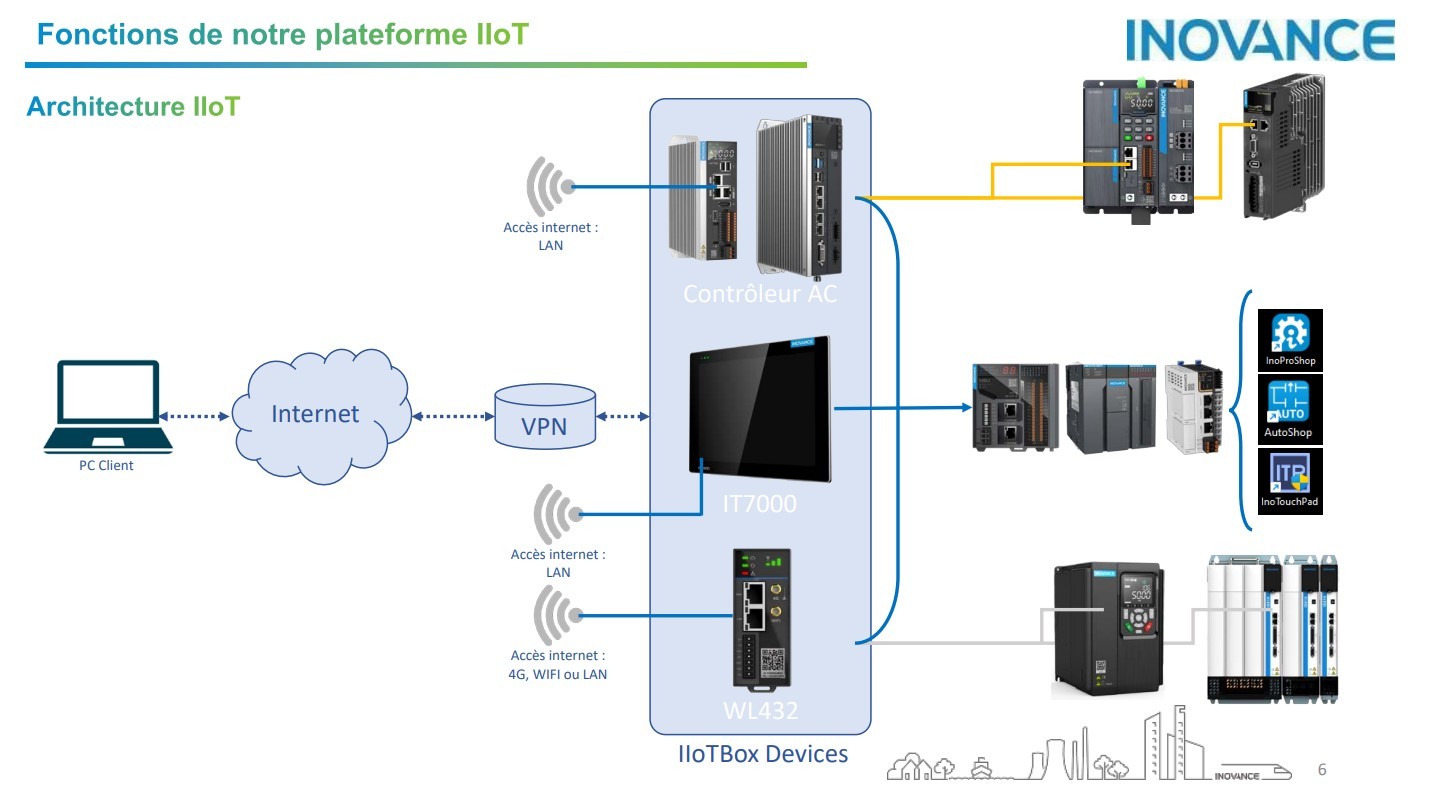

How this works in practice is shown in the diagram below from our partner for frequency controllers, servo systems and PLCs:

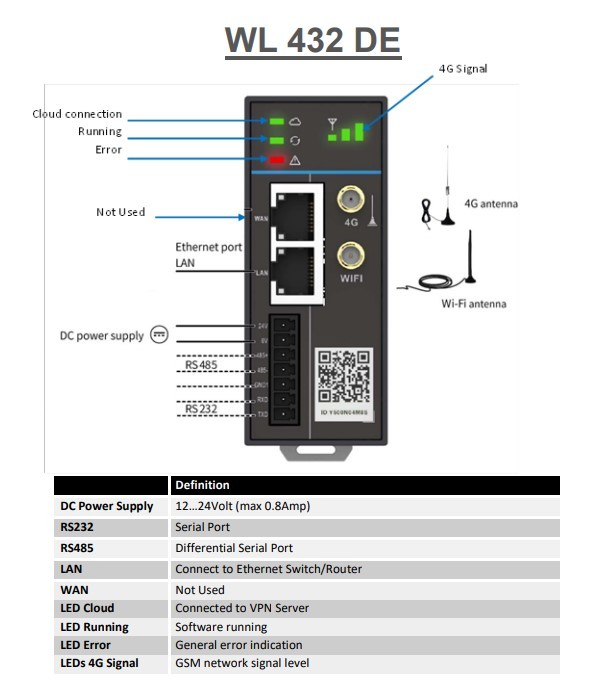

The IIoT Box Devices connect to the VPN Server 'JUPITER'. This can be done with a cable connection, 4G or via WiFi. An example of an IIoT Device is the WL 432 DK from Inovance :

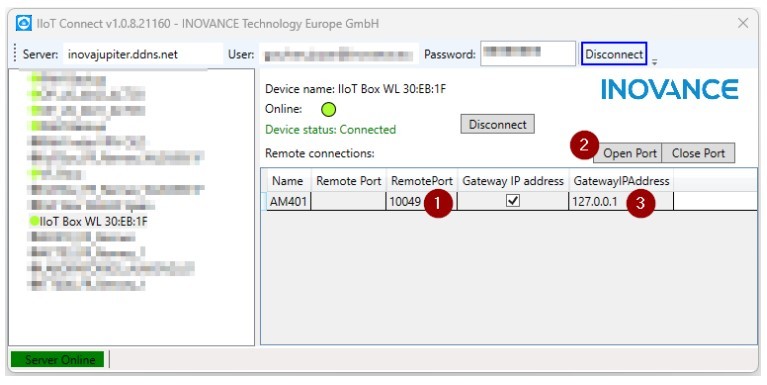

The protected IIOTConnect software environment then allows you to log in to this server in a secure manner and connect to the IIoT device..

Once the connection has been established, the user gains access to all relevant information available at machine level.

Questions about IoT in combination with electric drives or actuators? Don't hesitate to contact us at info@actintime.be !