In an era where machine building increasingly demands miniaturization and high precision, choosing the right drive technology is crucial. The latest actuators and stepper motors from our partners Oriental Motor and HaydonKerk demonstrate how their continuous pursuit of innovation has led to solutions in a form factor that was previously considered impossible. In this article, we highlight the operation of the linear actuator. A blog on rotary solutions will follow later.

Technology behind the Size 6 actuator

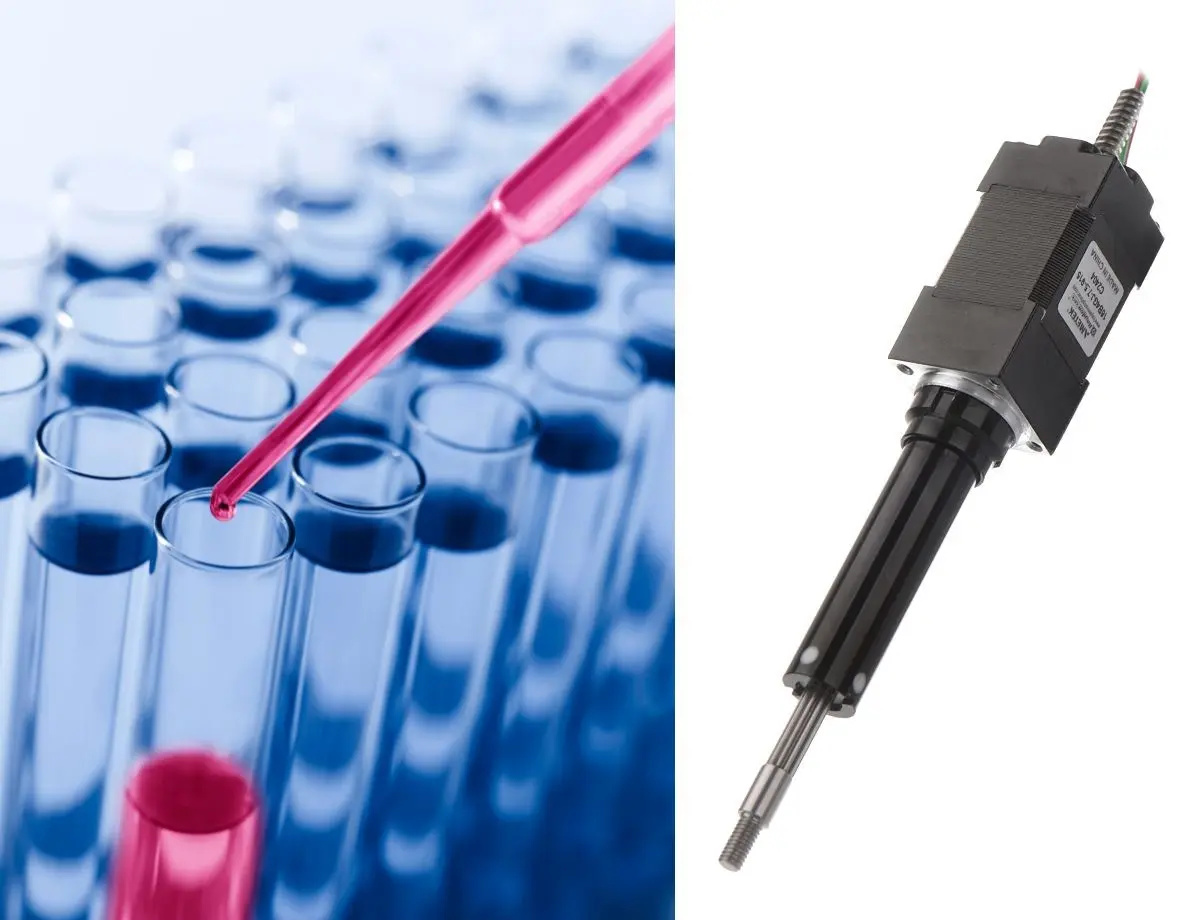

The new Size 6 linear actuator from HaydonKerk is based on a hybrid stepper motor with an integrated, self-lubricating nut and precision-ground spindle, efficiently converting rotation into linear motion. This results in a compact, strong, and highly accurate solution.

Key technical features:

- Frame size: 16mm (Size 6)

- Linear resolution: 0,0025 to 0,067 mm per step (depending on spindle lead)

- Maximum force: up to 50N

- Configurations: captive, non-captive, external linear

- Weight: 39 gr.

Options:

Encoders, home switch, proximity sensor, TFE-coated spindle, anti-backlash nut.

Benefits for machine building

Compact design with high force:

With a frame size of only 16 mm (0.6 inch), the Size 6 actuator is the smallest hybrid linear actuator in the HaydonKerk Pittman range, yet it delivers up to 50 N of linear force!

This allows integration into extremely compact systems such as medical devices, laboratory robots, and miniature mechanics.

High precision:

Thanks to the 3° step angle combined with a wide choice of spindle leads, the actuator offers a linear resolution from 0.0025 mm to 0.067 mm per step. This enables highly precise positioning down to the micron level. For applications requiring feedback, an encoder option is available (up to 4000 CPR / 16000 PPR).

Low Maintenance:

The actuator has few moving parts and can optionally be equipped with a TFE-coated spindle, eliminating the need for lubrication. This minimizes maintenance and extends service life, even under continuous operation. The H insulation class (max. 180°C) contributes to reliability in demanding environments.

Flexibility:

The Size 6 is available in captive, non-captive, and external linear versions, with various standard stroke lengths (from 9 mm to 38.1 mm) and accessories such as home sensors, anti-backlash nuts, and connectors for a tailored solution to your application.

Applications

The Size 6 actuator is widely applicable in sectors where precision and reliability are key, including:

- Medical devices: accurate dosing and positioning.

- Laboratory automation: pipetting systems and sample handling.

- Optical systems: lens positioning and focusing mechanisms.

- Semiconductor industry: wafer handling and micropositioning.

Design recommendations

When integrating into a machine building project, it is important to:

- choose the correct spindle lead based on required force, speed, and resolution

- match stroke length and configuration to the mechanical environment

- optimize driver selection to avoid unwanted vibration and noise

- monitor thermal limits during continuous operation

Innovation and trends

The trend toward miniaturization and smart automation makes compact actuators such as the Size 6 increasingly important. In combination with IoT connectivity and advanced control electronics, these actuators can become part of data-driven production environments, where predictive maintenance and real-time monitoring are the standard.

Are you working on a new design or project where precision, reliability, and compactness are central? Contact us to discover how the Size 6 actuator or another solution from the Act in Time portfolio—can take your project to the next level..

Download the Size 6 actuator datasheet here!