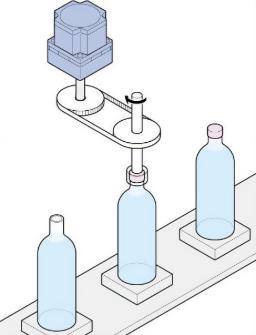

In the food and packaging industry, reliability, speed and hygiene are absolute prerequisites. The process of accurately closing bottles with caps often plays a crucial role in this. With the BLE2 motor series from Oriental Motor , Act In Time offers an innovative and compact solution that optimally combines precision, power and food safety. Discover how this technology makes your packaging line more efficient and reliable.

Automatic and controlled tightening: essential for the food industry

In the production and packaging lines of the food and beverage industry, it is of great importance that caps are always applied correctly and firmly. Only then are leaks excluded and product quality is guaranteed. The BLE2 motor series ensure reliable automation of this process within filling machines, where precise force control and constant performance are central.

The BLE2 motor series as a perfect match

The BLE2 motor series from Oriental Motor consist of a brushless DC motor in combination with an external, digital controller. This setup offers extremely precise torque control, constant speed and easy control via external signals or Modbus (RTU).

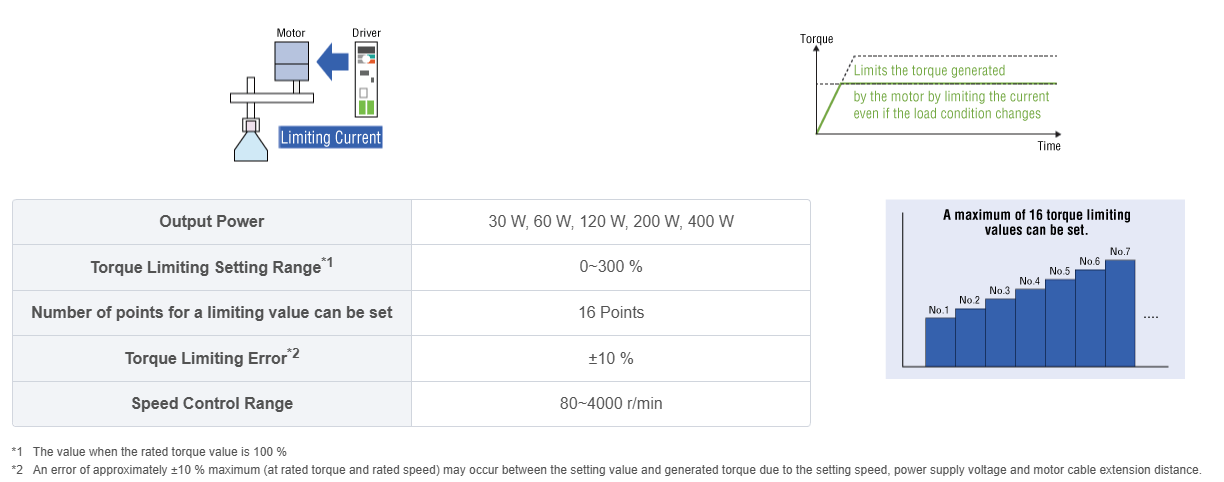

A major advantage is the presence of an electronic torque limiter. This allows the maximum torque to be set by software, which is essential for automatic cap tightening. This prevents bottles or caps from being damaged in the event of overload. This results in a controlled, repeatable process with consistent quality — even with variations in bottle shape or material thickness.

Thanks to the flexible combination of motor and external controller, both components can be optimally positioned within the machine design, which simplifies installation, even in existing and compact filling machines.

A special food grade version is also available for applications in the food industry. This uses H1 food-grade lubricants — greases that are registered with the NSF (National Sanitation Foundation).

H1 greases are approved for applications where incidental contact with food is possible. NSF is an internationally recognized certification body that monitors food safety and public health.

This feature makes the BLE2 food grade solution particularly suitable for use in hygiene-sensitive applications such as food cappers and other parts of the filling and packaging line.

Benefits for your packaging process:

- Consistent quality: precise torque control and electric torque limiter prevent damage and guarantee reliable sealing

- Flexible installation: external controller and compact motor design make integration into any filling machine easy

- Increased efficiency: automation increases throughput and reduces manual handling

- Less product loss: consistent performance ensures fewer errors and less downtime

- Hygienic and safe: food grade version with NSF-certified H1 lubrication offers certainty in critical environments

Act In Time: your partner in high-quality packaging automation

At Act In Time, we are happy to advise and guide you in optimizing your packaging lines with advanced technologies such as the BLE2 motor series. Thanks to our expertise in mechatronics and industrial automation, we offer solutions that perfectly match the high demands within the food and packaging industry.

Want to know more about the BLE2 motor series and the food grade possibilities? Contact us today for a no-obligation consultation and discover what this technology can do for your production line.