Act In Time is involved in the development of high-tech bioreactors that are used for the development of vaccines. This can be on a small or slightly larger scale: the smallest model is a table model that can be used for development and testing. The largest model is a lot larger, but remains mobile. These devices can be used, for example, to develop the necessary vaccines in small doses in disaster areas if the on-site capacity is lacking, insufficient or temporarily unavailable. Such mobile reactors also allow vaccines to be developed in a highly targeted and inexpensive manner.

Some vaccines - such as that for polio, for example - often consist of multiple active ingredients, but this is not always necessary in disaster areas. The production of these extensive vaccines may become too expensive, but with these reactors it is possible to produce a vaccine with only the most necessary ingredients. This makes it much cheaper to work.

DC motors dosing difficult

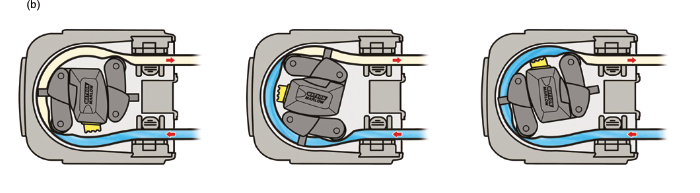

The flawless operation of bioreactors hinges on the quality of the dosing. This is guaranteed by Watson pumps. These work on the principle of a peristaltic pump: moving the product through a tube by alternately pressing and releasing it. The operation can be compared somewhat to the human body where blood, oxygen and nutrition are pumped through our bodies. A smooth, flexible hose lies inside the pump housing and is pressed completely tight against the wall of the housing. This is done by two or more shoes or rollers mounted on a rotor. After releasing the hose, an almost complete vacuum is created, which causes the product to be 'sucked' into the hose. When the product reaches the end of the hose, it is 'pushed' out of the hose. However, these peristaltic pumps are often driven by small DC motors, which does not always produce a quality result.

Variable loads

Dosing is obviously very important in this type of application, in addition to tracking. If the viscosity of the fluids used changes, for example, DC motors do not have the ability to respond to this, as their speed depends on the larger or smaller load. The control range is also important: the pumps must be able to switch quickly, say between say 50 and 500 rpm. DC motors fall somewhat short there too. In addition, synchronous operation is also important, as there are several peristaltic pumps in this installation and the delivered quantities must be able to be adjusted very accurately. A last -but not least- requirement of these customers is traceability. They want to be able to log every event in the production process for later recall. The Servo Stepmotor lallows sophisticated control. We worked out a system using JVL Servo-Step motors with integrated control. They are connected to the PLC via Profinet and can communicate with each other. This is important to ensure synchronous operation.

The stepper motor is further controlled like a servo motor. The speed of these pumps is typically maximum around 500 to 600 rpm. That is why we do not work with a classic servo motor, because at its typical speed of 3000 to 4000 rpm, a reduction gearbox would be needed. In this case, there was a certain need for compactness of the machine, so the space for this was not available. Dosing can also be much finer this way because the control range of the Servo Stepmotor is better matched to that of the peristaltic pumps. The unit also has an IP rating that prevents corrosion. This further guarantees reliability. A requirement that has become common in recent years, especially in pharma, is traceability. Because everything is fed back via the PLC speeds, velocities, positions, quantities, etc., this can be achieved. This information can also be consulted remotely

A servo stepmotor(a) optimises the accuracy of the feed to the bioreactor via a peristaltic pump (b).

Start hier met schrijven...