SATTRI EUROPE bv, based in Belgium and founded in 1998, has focused since its inception on providing high-quality laboratory lines for the production of technical yarns and fibers. With over 30 years of accumulated expertise, SATTRI offers customized solutions for the polymer industry. One of their leading product lines is the DIVIDO Line, a melt-spinning laboratory line specifically designed for testing, analyzing, and producing customized yarns and filaments. This line is used worldwide for various applications, including the production of technical fibers and the testing of new materials.

To build the necessary quality, durability, and accuracy of our controls, various components were selected over the years from different suppliers worldwide. The collaboration and support from Act In Time, along with the provided control systems, proved to be a perfect fit for us. Our expectations regarding quality, performance, delivery times, and cost were more than met.

(Freddy Van Tricht - Owner Sattri Europe bv)

Schrijf iets...

Schrijf iets...

Multi-Axis Frequency Control MD800: A Cost-Effective and Space-Saving Solution

To further enhance the efficiency of the melt-spinning line and save space, SATTRI opted for the implementation of the Inovance

MD800 inverter. This multi-axis frequency control manages the speed of seven permanent magnet motors. Perfect speed control of the PM motors is crucial for the operation of various rollers, including roll1,

roll2, roll3, as well as the winder, take-up and spinning pump. These motors are driven in open-loop synchronization, with speeds of up to 12,000 RPM being essential for the quality of the final product.

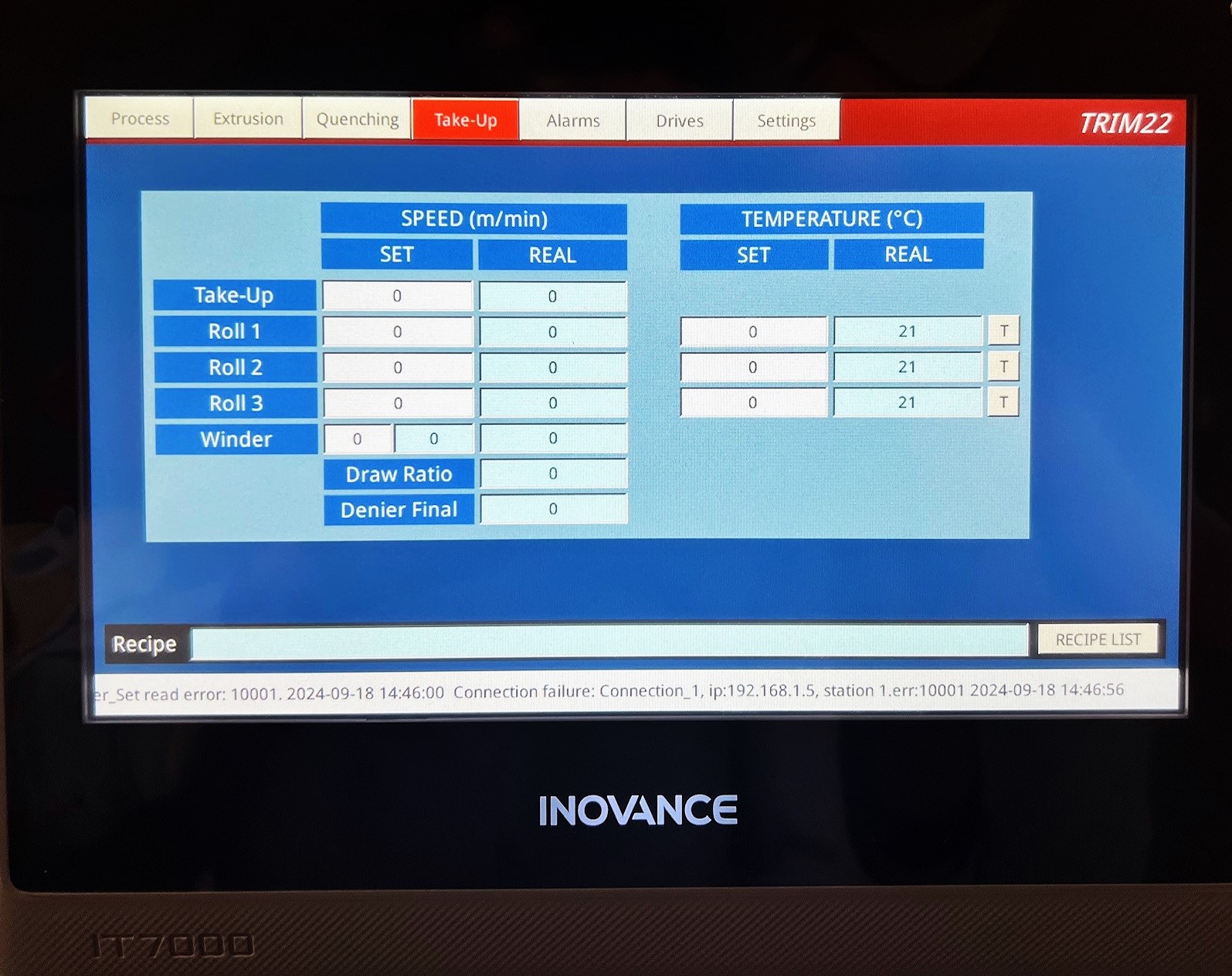

Innovative communication via EtherCAT

In the initial machines, CAN communication was used for control, but to improve the performance and speed of the system, SATTRI decided to switch to EtherCAT communication between the PLC and the frequency converters. EtherCAT offers higher speed and reliability, which is crucial for accuracy in the yarn production process. The use of EtherCAT enables SATTRI to facilitate real-time communication between the control systems, benefiting overall productivity and product quality.

One supplier, full support

For the customer, it was important to find a one-stop-shop

solution where all necessary components could be supplied by a single supplier. This facilitated the integration of control systems, including the PLC (AM320) and the HMI (IT7100).

Through this integrated approach, combined with local support and a cost-effective solution, SATTRI offers its customers a seamless experience from design to implementation.

All Inovance products are license-free, meaning that customers do not have to pay additional fees for software licenses or updates.

The collaboration between SATTRI and Act In Time has resulted in an advanced, reliable, and future-oriented machine that meets the needs of customers to develop and test innovative polymers and filaments.

Would you also like to see your application example in our newsletter? Share your story with us and who knows, your application might be in the spotlight next time! Contact us for more information.